Product Categories

Colored PTFE Capillary Ptfe Teflon Tube Low Flammability

Product number:Colored PTFE Capillary Ptfe Teflon Tube Low Flammability

Quick Overview: Place of Origin: China (Mainland) Certification: SGS,IOS9001,ISO14001

Send Inquiry

PDF DownLoad

Product Description

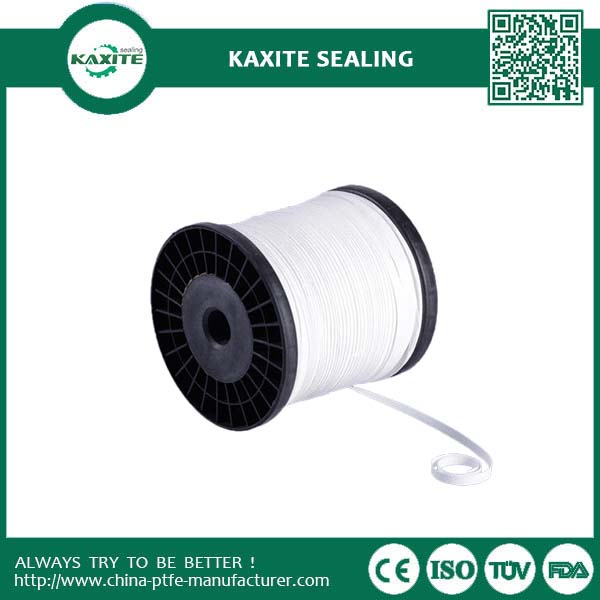

PTFE tube is manufactured by technics of molding method in the out diameter from 25 to 1200mm with PTFE granular resin. As PTFE has a very low co-efficient of friction, so the surface of extruded teflon PTFE tube has similar friction levels to ice. Extruded teflon PTFE tube can work at -180°C ~+260°C and is the best electrical insulator of all known plastics.

Packaging & Delivery

Packaging Details:Plywood cases that don't need fumigation. Other packing is customized according to client's requirements

Delivery Detail: normally 15-30 days

High quality ptfe tube

100% virgin PTFE/Teflon tube are made by plunger extrusion of suspension polymerized PTFE resins. So that the fiber orientation, and after drying, high temperature sintering, shaping process and made of hose, usually packed in roll.

Main properties

|

Properties |

Unit |

Result |

|

Apparent density |

g/cm3 |

2.10-2.20 |

|

Tensile strength (min) |

MPa |

20 |

|

Ultimate elongation (min) |

% |

200 |

|

Residual Lubricant Content (max) |

% |

0.5 |

|

Dialectric Strength (min) |

KV/mm |

10 |

Features

PTFE tubing is manufactured by ram extruding method with PTFE granular resin.

PTFE is the most chemical-resistant of all knownPlastics. It Has the best electrical properties of plastics.

Low flammability

Low coefficient of friction

This PTFE teflon oil seal has low dielectric constant

Low water adsorption

best corrosion-resistant

Good weathering properties

PTFE resin,filled with some filling stuff,can prolong the life of products and strengthen the performance,eg:Graphite,Carbon ,Glass fiber ,bronze

|

Glass Fiber: |

Increases compressive strength, rigidity and wear. |

|

Carbon: |

Increases compressive strength, hardness, wear, and load properties. |

|

Graphite: |

Reduces coefficient of friction |

|

Molybdenum Disulfide: |

Increases hardness, stiffness, and wear |

|

Bronze: |

Increases hardness and wear resistance |