Product Categories

Different Size Moulded Rod Filled Ptfe Products For Producing Bearings

Product number:Different Size Moulded Rod Filled Ptfe Products For Producing Bearings

Quick Overview: Place of Origin: China Certification: ISO 9001,ROHS

Send Inquiry

PDF DownLoad

Product Description

PTFE

Rod is often chosen to produce bearings because of its very low

friction and also for its free running ability. Because of its ability

to conform to shape otherwise known as flow, PTFE Rod is used for seals

in valves, this is because it can conform to shape and create a high

specification valve seal. PTFE Rod can easily be machined but due to the

surface softness, care must be taken in lathe jaws or high compressive

loads, which may cause distortion. Another important element to remember

regarding PTFE Rod is the coefficient of expansion due to heat changes;

this can be uneven with PTFE and may cause distortion in components.

Specifications:

Specifications:

PTFE

Rod is manufactured in two distinct ways, extruded PTFE Rod is the most

popular and is relevant to smaller sizes, Moulded PTFE Rod is relevant

to the diameters over 100mm in size, smaller sizes are also available in

extruded form.

(a) Sizes Availabe,

-Extruded Rod Min. Diameter= 5mm, Max. Diameter= 150mm,

Length= normal 1 m, or according to customer's request

-Moulded Rod Min. Diameter= 5mm, Max. Diameter=300mm,

Length: Max. 300mm

(b) Extruded Rod Diameter 4~9mm made from dispersion PTFE resin; Diameter 10~50mm made from dispersion PTFE resin

Products Keywords

Related Products

High Temperature Resitance Filled Ptfe Products For Heat Press Machine

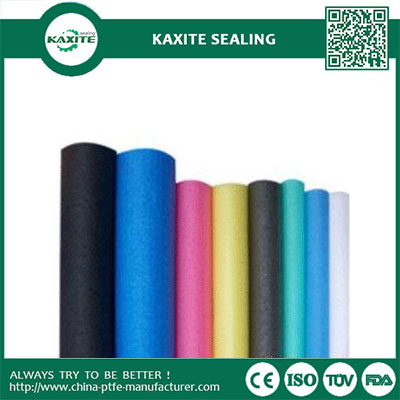

Colorful Pigment Filled PTFE Gasket Compression Recovery Sealing Performance

Gasket Filled Ptfe Products With Recovery Sealing Performance

Glass Graphite Bronze Filled PTFE Gasket Good Compression Strength

Graphite Filled PTFE Gasket For Chemical Industry Power Plant

Graphite Glass Fiber Filled PTFE Skived Sheet Non-Stick Anti-aging

Bronze carbon Filled PTFE Rods For Seals In Valves Low Friction Block

Custom Graphite Filled PTFE Gasket For Hydrocarbon Reaction Power

Bronze Filled PTFE Gasket Has Compression Recovery Sealing Performance

Glass Filled PTFE gasket Wear Resistance For Hydrocarbon Reaction

Carbon Fiber Filled Ptfe Skived Sheet Corrosion-Resistant

Moulded Bronze Filled PTFE Tube PTFE Filling Pipe

Dispersion PTFE Resin Carbon Filled Ptfe Tube Graphit Filled PTFE Products

Self-Lubricating Bronze Powder Filled PTFE Skived Sheet Filled Ptfe Products

Extruded glass filled ptfe Rod For Seals In Valve

Glass Bronze Filled Teflon Gasket Filled PTFE Gasket For Power Plant

Suspension PTFE Molybdenum Disulfide Filled Ptfe Tube

Decreased Thermal Expansion Graphite Filled Ptfe Sheet Products

Different Size Moulded Rod Filled Ptfe Products For Producing Bearings

Copper Wire Filled Ptfe Packing Braided With Filamentand For Chemical Compounds