Product Categories

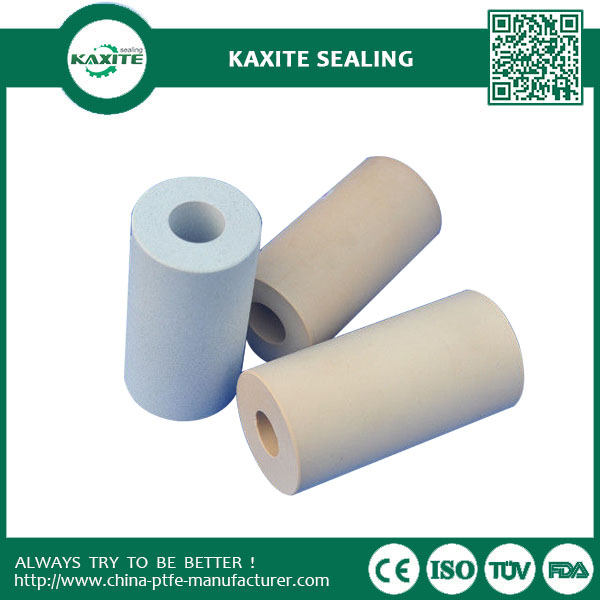

Graphite Filled Black Ptfe Teflon Tube Wear-Resisting For Chemistry

Product number:Graphite Filled Black Ptfe Teflon Tube Wear-Resisting For Chemistry

Quick Overview: Place of Origin: China (Mainland) Certification: SGS,ISO9001,ISO14001,FDA

Send Inquiry

PDF DownLoad

Product Description

Main properties

|

Properties |

Unit |

Result |

|

Apparent density |

g/cm3 |

2.10-2.20 |

|

Tensile strength (min) |

MPa |

20 |

|

Ultimate elongation (min) |

% |

200 |

|

Residual Lubricant Content (max) |

% |

0.5 |

|

Dialectric Strength (min) |

KV/mm |

10 |

Specifications of PTFE tube:

|

Type |

(mm) ID |

(mm) OD S Type |

(mm) OD T Type |

(mm) OD L Type |

Packing(M/R) |

|

30 |

0.30±0.10 |

0.80±0.10 |

0.70±0.10 |

0.60±0.10 |

305 |

|

28 |

0.38±0.10 |

0.88±0.10 |

0.78±0.10 |

0.68±0.10 |

305 |

|

26 |

0.46±0.10 |

0.96±0.10 |

0.86±0.10 |

0.76±0.10 |

305 |

|

24 |

0.56±0.10 |

1.16±0.10 |

1.06±0.10 |

0.86±0.10 |

305 |

|

23 |

0.66±0.10 |

1.26±0.10 |

1.16±0.10 |

0.96±0.10 |

305 |

|

22 |

0.71±0.10 |

1.31±0.10 |

1.21±0.10 |

1.01±0.10 |

305 |

|

21 |

0.81±0.10 |

1.41±0.10 |

1.31±0.10 |

1.11±0.10 |

305 |

|

20 |

0.86±0.10 |

1.66±0.10 |

1.46±0.10 |

1.16±0.10 |

305 |

|

19 |

0.96±0.20 |

1.76±0.20 |

1.56±0.20 |

1.26±0.20 |

305 |

|

18 |

1.07±0.20 |

1.87±0.20 |

1.67±0.20 |

1.37±0.20 |

305 |

|

17 |

1.19±0.20 |

1.99±0.20 |

1.79±0.20 |

1.49±0.20 |

305 |

|

16 |

1.34±0.20 |

2.14±0.20 |

1.94±0.20 |

1.64±0.20 |

305 |

|

15 |

1.50±0.20 |

2.30±0.20 |

2.10±0.20 |

1.80±0.20 |

153 |

|

14 |

1.68±0.20 |

2.48±0.20 |

2.28±0.20 |

2.08±0.20 |

153 |

|

13 |

1.93±0.20 |

2.73±0.20 |

2.53±0.20 |

2.33±0.20 |

153 |

|

12 |

2.16±0.25 |

2.96±0.25 |

2.76±0.25 |

2.56±0.25 |

153 |

|

11 |

2.41±0.25 |

3.21±0.25 |

3.01±0.25 |

2.81±0.25 |

153 |

|

10 |

2.69±0.25 |

3.49±0.25 |

3.29±0.25 |

3.09±0.25 |

153 |

|

9 |

3.00±0.25 |

4.00±0.25 |

3.80±0.25 |

3.40±0.25 |

100 |

|

8 |

3.38±0.25 |

4.38±0.25 |

4.18±0.25 |

3.78±0.25 |

100 |

|

7 |

3.76±0.25 |

4.76±0.25 |

4.56±0.25 |

4.16±0.25 |

100 |

|

6 |

4.22±0.25 |

5.22±0.25 |

5.02±0.25 |

4.80±0.25 |

100 |

|

5 |

4.72±0.25 |

5.72±0.25 |

5.52±0.25 |

5.32±0.25 |

100 |

|

4 |

5.28±0.30 |

6.28±0.30 |

6.08±0.30 |

5.88±0.25 |

100 |

|

3 |

5.94±0.30 |

6.94±0.30 |

6.74±0.30 |

6.54±0.25 |

100 |

|

2 |

6.68±0.30 |

7.68±0.30 |

7.48±0.30 |

7.28±0.25 |

100 |

|

1 |

7.46±0.30 |

8.46±0.30 |

8.26±0.30 |

8.06±0.25 |

100 |

|

0 |

8.38±0.30 |

9.38±0.30 |

9.18±0.30 |

8.98±0.25 |

100 |

Description

PTFE tube adopt import high-quality PTFE resin (PTFE, commonly known as Teflon, plastics king), extrusion agglutination formation. The product has thermostablly, inoxidizability, wear-resisting, self-lubrication merit.Teflon tube can be widely used in science & technology field, such as in chemistry, instruments, mechanical industries, astronautic industry, vehicles, transformers, communications, etc.

|

Glass Fiber: |

Increases compressive strength, rigidity and wear. |

|

Carbon: |

Increases compressive strength, hardness, wear, and load properties. |

|

Graphite: |

Reduces coefficient of friction |

|

Molybdenum Disulfide: |

Increases hardness, stiffness, and wear |

|

Bronze: |

Increases hardness and wear resistance |

Features

1)PTFE TUBE Anti-corrosion in all kinds of chemicals including nitric acid & aqua fortis.

2)PTFE TUBE Characteristics:Low friction,Virtually no lubrication

requirement,Light weight,Resistant to corrosion and abrasion, Impact

resistance,Stable chemical properties,Oil resistance,High temperature

resistance,Low temperature resistance,water resistance and so on.

3)PTFE TUBE working temperature:-55~+260°C.

4)PTFE TUBE Electric insulation;good dielectric in mediums.

5)PTFE TUBE filled ptfe tube products(plastic tube pipe) Made of high-speed mixing polytetrafluoroethylene resin and certain filling resin

6)PTFE TUBE Soft and formable,Outstanding chemical properties etc.