Product Categories

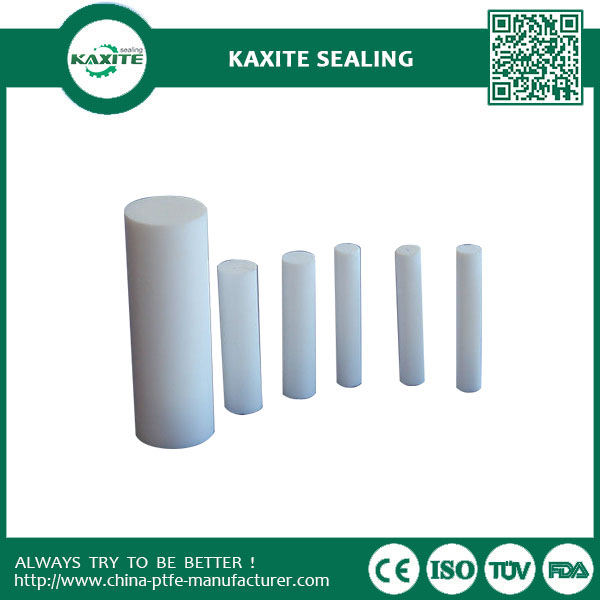

Moulded Graphite Ptfe Teflon Rod For Aerospace Industry Electrical Resistance

Product number:Moulded Graphite Ptfe Teflon Rod For Aerospace Industry Electrical Resistance

Quick Overview: Place of Origin: China

Send Inquiry

PDF DownLoad

Product Description

1.Extruded Rod,Moulded Rod

2.Any sizes according to customer's demand

3.Carbon, graphite can be filled

PTFE

Rod is manufactured in two distinct ways, extruded PTFE Rod is the most

popular and is relevant to smaller sizes, Moulded PTFE Rod is relevant

to the diameters over 100mm in size, smaller sizes are also available in

extruded form.Molded Teflon rod has a wide range of practicable

temperature from -180°C - +260°C and a wax-like surface to which

anything hardly rods. Molded PTFE rod has the lowest coefficient of

friction of all known solid materials. It has the best electrical

properties of all plastics.

Applications for PTFE Rod:

PTFE

is excellent for low friction bearings, bushes, rollers and pulleys.

PTFE is also almost exclusively used in cryogenic components due to its

ultra low operating temperatures. PTFE Rod is regularly used for seals.

PTFE Rod has become a very important engineering plastic used within the

aerospace industry and aeronautics. PTFE is often used within the food

industry companies. Another useful application over the years has been

in the use of product or component handles due to its resistance to heat

and heat transfer. When an application for electrical resistance

becomes too high for other materials, PTFE Rod can fill a very important

gap.