Product Categories

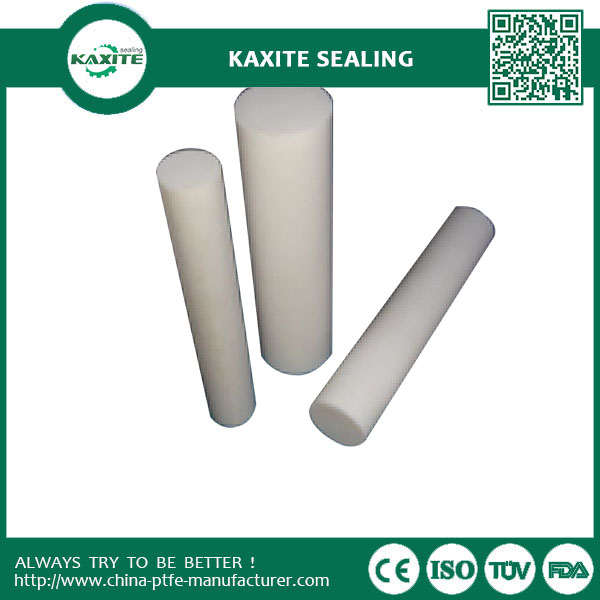

Moulded dielectric non-ageing airproof ptfe teflon rod with ISO9001 certification

Product number:Moulded dielectric non-ageing airproof ptfe teflon rod with ISO9001 certification

Quick Overview: Place of Origin: China Certification: ISO 9001,ROHS

Send Inquiry

PDF DownLoad

Product Description

PTFE

Rod is often chosen to produce bearings because of its very low

friction and also for its free running ability. Because of its ability

to conform to shape otherwise known as flow, PTFE Rod is used for seals

in valves, this is because it can conform to shape and create a high

specification valve seal. PTFE Rod can easily be machined but due to the

surface softness, care must be taken in lathe jaws or high compressive

loads, which may cause distortion. Another important element to remember

regarding PTFE Rod is the coefficient of expansion due to heat changes;

this can be uneven with PTFE and may cause distortion in components.

PTFE Rod have some excellent properties of enduring

chemeistry&corrosiveness, dielectric, non-ageing, airproof, hight

lubricity and has a wide range of practicable temperature from

-180-+250° C and a wax-like surface where anything hardly sticks on and

the lowest coefficient of friction of all known solid materials.

Application

PTFE molded rod is use of the products the electrical insulation used under various kinds of frequency, the sesal liner of various kinds of corrosivity medium, antisticking materials, lubriation material.

Related Products

Graphite Filled Smooth Ptfe Teflon Rod Extruded Bar Moulded Non Aging Ptfe Rod

Extruded Ptfe Teflon Rod Bar Stock Graphite Carbon Filled Teflon

Colorful Smooth Non Stick Ptfe Teflon Rod Extruded Bar Round Bar

PTFE Material Glass Fiber Filled Ptfe Teflon Rod In 200mm Long

Virgin Colorful 1000mm Ptfe Teflon Rod White And Black

Corrosion Prevention F4 Ptfe Teflon Rod Round Bar Bronze Glass Fibre Ptfe

Virgin Pure Molded Ptfe Teflon Rod Extruded Bar Stock White Black Color

High Chemical Resistance Ptfe Teflon Rod Graphite Filled White Ptfe Bar

Fiber Glass Ptfe Teflon Rod Bar Stock White Molded Rod ISO9001 Certificate

Extruded PTFE Teflon Rod For Aerospace Industry Aeronautics

Virgin Moulded Ptfe Teflon Rod Coefficient Of Friction

Moulded Graphite Ptfe Teflon Rod For Aerospace Industry Electrical Resistance

Custom Designed Extruded Rod Moulded Rod PTFE Bar Ptfe Stick The Lowest Coefficient of Friction

Non-ageing Airproof virgin PTFE Teflon Moulded ROD Hight Lubricity Ptfe Teflon Rod

virgin PTFE Teflon Moulded ROD Non-ageing Airproof Hight Lubricity Ptfe Teflon Rod

Color PtfeTeflon Rod With The Lowest Coefficient Of Friction Working In -180°C - +260°C

Recycled Ptfe Teflon Rod Customers Demand With Carbon Graphite Glass Fiber

Teflon Ptfe Rod Extruded Rod Moulded Rod -180°C - +260°C With Best Electrical Properties

Moulded dielectric non-ageing airproof ptfe teflon rod with ISO9001 certification

White Black Custom Designed Ptfe Teflon Extruded Rod With Good Electrical Insulation